|

STRIP

PLANKING

BEYOND THE BASICS

A recent edition of Australian Amateur Boatbullder

contained an article 'Composite Strip Planking Basics'. There are a number

of difficulties involved in the conventional strip planking described,

which are generally ignored and left to the unfortunate boat builder to

discover the hard way. Since BoatCraft Pacific have been involved in

developing techniques to alleviate these difficulties, we will explain

these more modern and labour saving methods of strip planking.

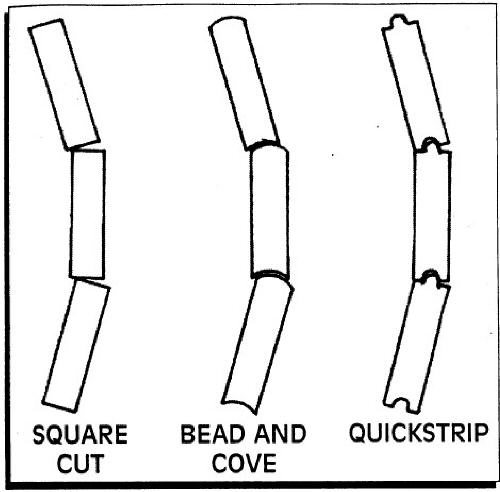

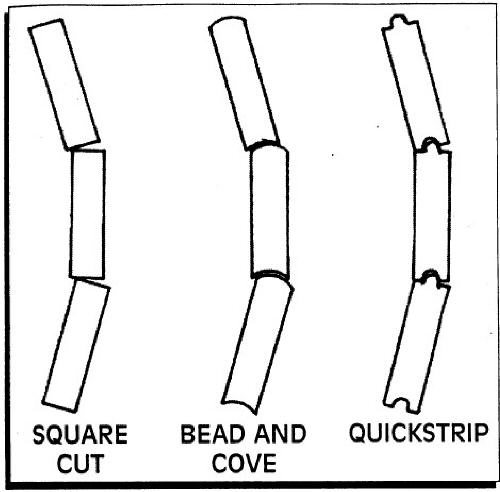

The difficulties builders encounter with conventional strip planking

are:

1. As you plank around the bilge of the boat,

differential twist between each plank and the next ea uses them to spring

sideways. '[his can produce steps between each plank. These steps can be

reduced, but rarely eliminated, by (tediously) fixing lots of transverse

pimood strips over the planks to try to force them down, or you will just

have to sand them away ro create a smooth surface for the fibreglass

lamination. Either way, there's hours of sanding, which is not much fun

especially inside a small craft like a canoe. This problem applies whether

you are using simple square sawn strips or bead and cove strips (see

diagram).

2. As was pointed out

previously, one of the more time consuming jobs is applying epoxy glue to

the strip edges.

3. IT your boar is

longer than 5m (16ft) it will be absolutely necessary to scarf join every

plank (other than few shorter ones near the keel) before you start

planking. Unfortunately, Western Red Cedar is no longer available in

lengths longer than 5.4 or 5,7m, which is about the length around the hull

of a 5m boat.

Enter QUICKSTRIP strip

planking profiles.

Quickstrip is a modified

tongue and groove profile, designed by Brisbane boat budder Christopher

Tuck, and manufactured exclusively by Oregon Sales. It has been engineered

to allow adjacent planks to rotate relative to each other by more than 15

degrees without losing register and slipping sideways. So Quickstrip

eliminates the steps on the surface and reduces sanding to a mere

smoothing job before fibreglassing. Of course, as with square cut planks,

the gaps between planks around the outside of the hull must be filled with

an epoxy sanding compound all over the surface, and wiping clean. Only a

light sand is required before glassing.

The

second benefit of Quickstrip is that scarfing the planks is no longer

necessary. The planks are simply butted up to each other and glued. The

butt joins can be cut at 90 or preferably at 45 degrees. The tongue and

groove each side of the plank holds the butt ends in perfect alignment

without any need to align and scarf join them beforehand.

The final improvement is the use of BoatCraft's Purbond adhesive. This

is a single pack moisture curing polyurethane adhesive, which expands

slightly as it sets so fills the small gaps between the Quickstrip (or any

other) profiles. A very small bead of Purbond is simply squeezed along

each groove, spread with a scrap of plank, and the plank is [lien ready to

be fixed. It is much easier and more time saving than mixing and spreading

epoxy, even when spreading onto several planks at once in a glueing

fixture. Purbond is also easier to clean up, since it does not blunt edge

tools like epoxy does. So you can plane down the exterior of the hull to

fair it, instead of creating vast clouds of sanding dust.

Purbond is

also much more economical. We have had builders strip planking the hulls

of large boats at a fraction of the cost of epoxy - a 9m strip planked

catamaran needs as little as 10 litres of Purbond, costing a mere $180!

Finally a word of caution. Of course, there are cheaper copies of

Quickstrip around. Router cutters can be purchased to mill your own

profiles. So far, we have not seen one which has been properly designed

and engineered to the accuracy standards that our tool makers acheived.

The result is that you, the long suffering boat builder, simply get to do

more sanding, just like the (bad) old days. Buyer Beware! You get just

what you pay for.

Quickstrip profiles are

stocked and distributed by BoatCraft Pacific. For further information on

Quickstrip techniques,

supply of Quikstrip in Western red Cedar,

Purbond adhesive, or Bote-Cote epoxy products call

BoatCraft Pacific on (07) 3806 1944 or any BoatCraft distributor.

Enquiries /font>

Please call Boatcraft Pacific

07 3806 1944 ( +617 3806 1944) for how to contact your nearest reseller.

Copyright Boatcraft Pacific Pty.

Ltd. |