|

|

|

14 Dulwich St., Loganholme, Queensland, 4129, Australia

P07 3806 1944 (+617 3806 1944) F07 3209 7711 (+617 3209 7711)

|

|

|

|

|

Conserving Carpentaria

|

|

|

|

|

|

|

|

|

|

The Queensland Maritime Museum chose

Feronite Rusty Metal Primer for its program to conserve "Carpentaria", a light ship

which was built in 1917 and was in service

until the early 1980's as a light ship near the

tip of Cape York.

After almost 100 years, Carpentaria is in

very poor condition, with rust holes com-

pletely thrugh its 15mm thick steel hull in

many places around the water line. To add

to the problems, it floated and capsized

when the dry dock filled with water during

the 2010 Brisbane river flood.

The Queensland Maritime Museum has

very little government funding and relies

almost completely on volunteer labour to

maintain and conserve its exhibits.

|

|

|

|

The Museum's objective was to reduce the

rate of deterioration as much as possible, and

to make the vessel into a presentable and at-

tractive exhibit. This had to be done with vol-

unteer labour, and at minimal cost. The close

proximity of residential apartments also pre-

cluded very noisy or dusty operations. This

ruled out the use of sand blasting, or other

complicated or expensive systems and meth-

ods. Based on 10 plus years experience with

the conservation of HMAS Diamantina, a paint

system based on Feronite Rusty Metal Primer

was chosen.

The work is being done by volunteers, so the

skills needed to be reasonable. Also the project

would need to be interrupted and undertaken as and

when volunteers were available. Additionally,

many volunteers are retired so that work need-

ing great physical exertion is out of the ques-

tion.

|

|

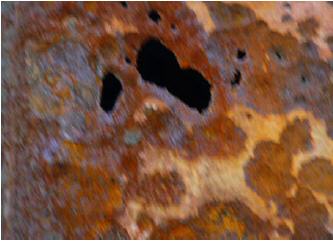

One of the many waterline rust holes.

Flaky rust which is removed by chipping and nee-

dle gunning.

|

|

|

|

Even though Carpentaria is in poor condition,

Feronite RMP does not require the metal to be pre-

pared to a high standard. The hull is chipped and nee-

dle gunned to remove lose flaking rust, and then wire

brushed to remove any residual loose material.

Once a section had been prepared, it is coated with 2 coats of

Feronite Rusty Metal Primer, applied using a brush. When dry, it is

then over-coated with 2 brushed coats of a high performance

universal alkyd primer(Interprime 198 Grey in this case), and

|

After 2 coats of Feronite Rusty Metal Primer.

|

|

|

|

finally brushed top-coat with a general purpose

high gloss enamel (alkyd) suited for steel structures (Interlac 649 Red and Black). Currently

the work is being undertaken by a single (retired) volunteer on a 2 day a week basis.

This preperation and painting schedule has been used very satisfactorily to keep HMAS Dia-

mantina in very good condition over the last 10 or so years. Head of maintenance, Alan

Bibbi says that the Feronite RMP makes a huge improvement in how long the coating stops

new rust appearing. The outcome is a good looking exhibit, which has had the rate of dete-

rioration greatly slowed for little more than the cost of the paint.

|

|

|

|

|

|

Enquiries

Please call Boatcraft Pacific

07 3806 1944 ( +617 3806 1944) for how to contact your nearest reseller.

Copyright Boatcraft Pacific Pty.

Ltd.

sitemap

|