|

|

|

|

|

|

HISTORYIt has been known for many years that vegetable tannins possess useful anti-corrosive properties. Old carpenters used to pack their tools in wood shavings to prevent them rusting. Everyone has seen how a nail driven into green timber develops a black stain on its surface and in the timber around it - this is the reaction product of iron oxide and the tannins in the wood, and it slows down the rusting process of the nail.

Chemical research into tannin technology was taking place in Europe during the 1970's, and Feronite is a result of that research.

HOW FERONITE STOPS RUSTAn iron surface is made up of microscopic positive (anodic) and negative (cathodic)

areas, In the presence of moisture, they react together and cause the surface to form a mixture of iron oxides. The anodic area is the one where metal actually reacts or dissolves to form the oxide, but, as the chemical nature of the surface continually changes, the cathodic and anodic areas tend to move around so that corrosion takes place over all of the surface.

Feronite reacts with rust to produce a different form of iron oxide together with iron tannate. This layer is both insoluble and passive to further corrosion.

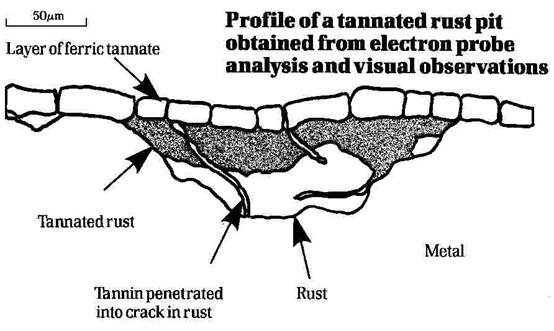

Scientific analysis of a rusted surface shows a picture of a reduced oxide (ferrous oxide) at the steel interface covered with tannated iron oxides and a final reaction of ferric tannate on the outer surface. The whole surface is more strongly bonded than the original ferric oxide rust layer, and the scaly or 'reticulated' ferric tannate surface acts as an excellent key for follow on paint systems,

This product should only be used in accordance with instructions on the container label or written instructions from the company. This is not a specification and all information is given in good faith. For application in special conditions, consult BoatCraft Pacific Pty. Ltd. or an appointed agent for detailed recommendations. The manufacturer warrants that its products have been manufactured under strict control to its normal standards. The performance of the product will vary according to the nature of the surface to which it is applied and the preparation and the mode of application. As the manufacturer cannot supervise the above procedure no warranty as to fitness of the product for a particular purpose can be given provided that nothing herein shall be deemed to exclude, restrict or modify any conditions or warranty expressed or implied by any statute whether State or Federal. Enquiries Please call Boatcraft Pacific 07 3806 1944 ( +617 3806 1944) for how to contact your nearest reseller. Copyright Boatcraft Pacific Pty. Ltd. | |||